Designers can create thinner profiles for the windows, enhancing the view and the amount of natural light that enters a room Designers can create thinner profiles for the windows, enhancing the view and the amount of natural light that enters a room

Designers can create thinner profiles for the windows, enhancing the view and the amount of natural light that enters a room Designers can create thinner profiles for the windows, enhancing the view and the amount of natural light that enters a room aluminum sliding window wheels. In addition, aluminum's inherent strength enables larger window sizes, further optimizing the indoor-outdoor connection.

aluminum sliding window wheels. In addition, aluminum's inherent strength enables larger window sizes, further optimizing the indoor-outdoor connection.Durable and Weather-Resistant

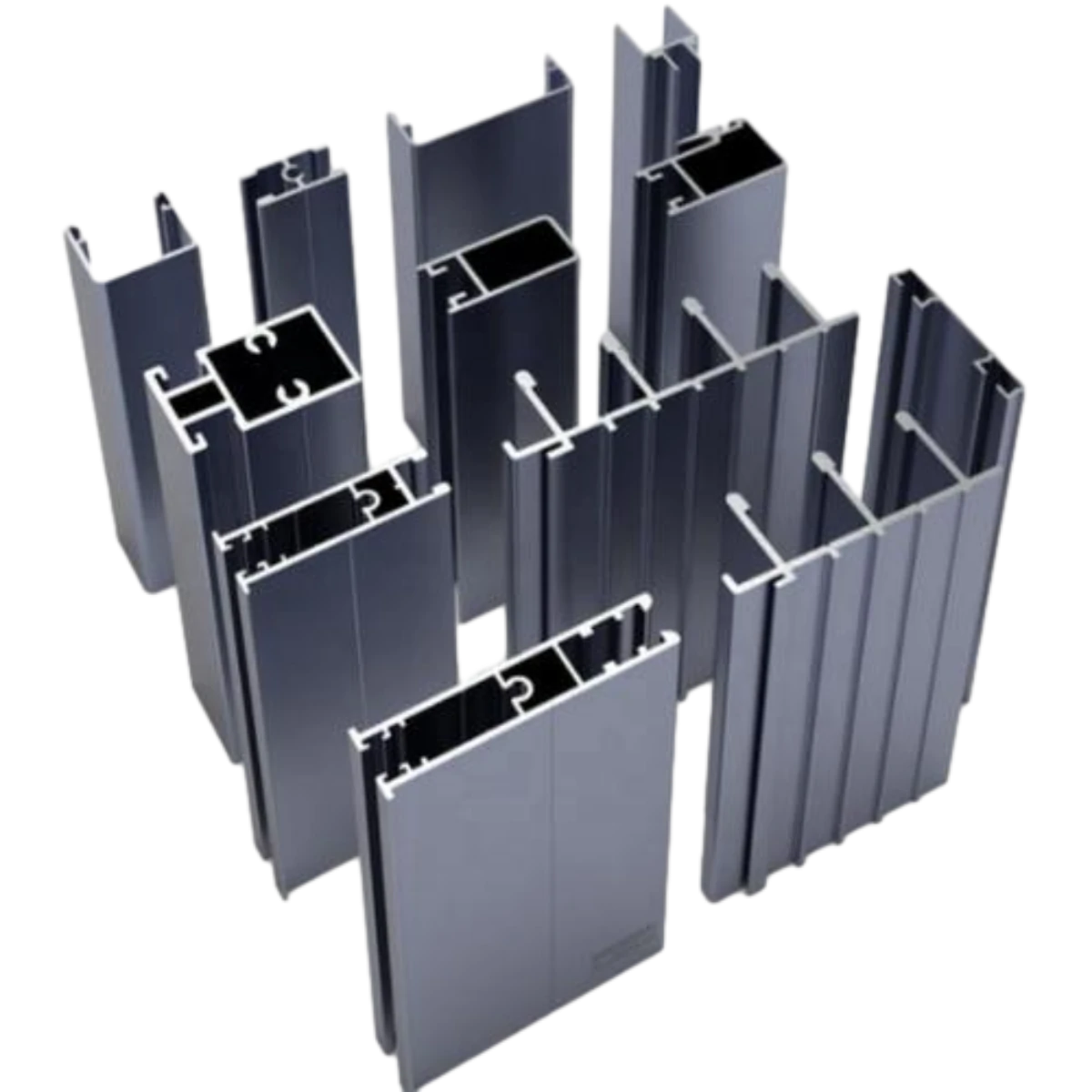

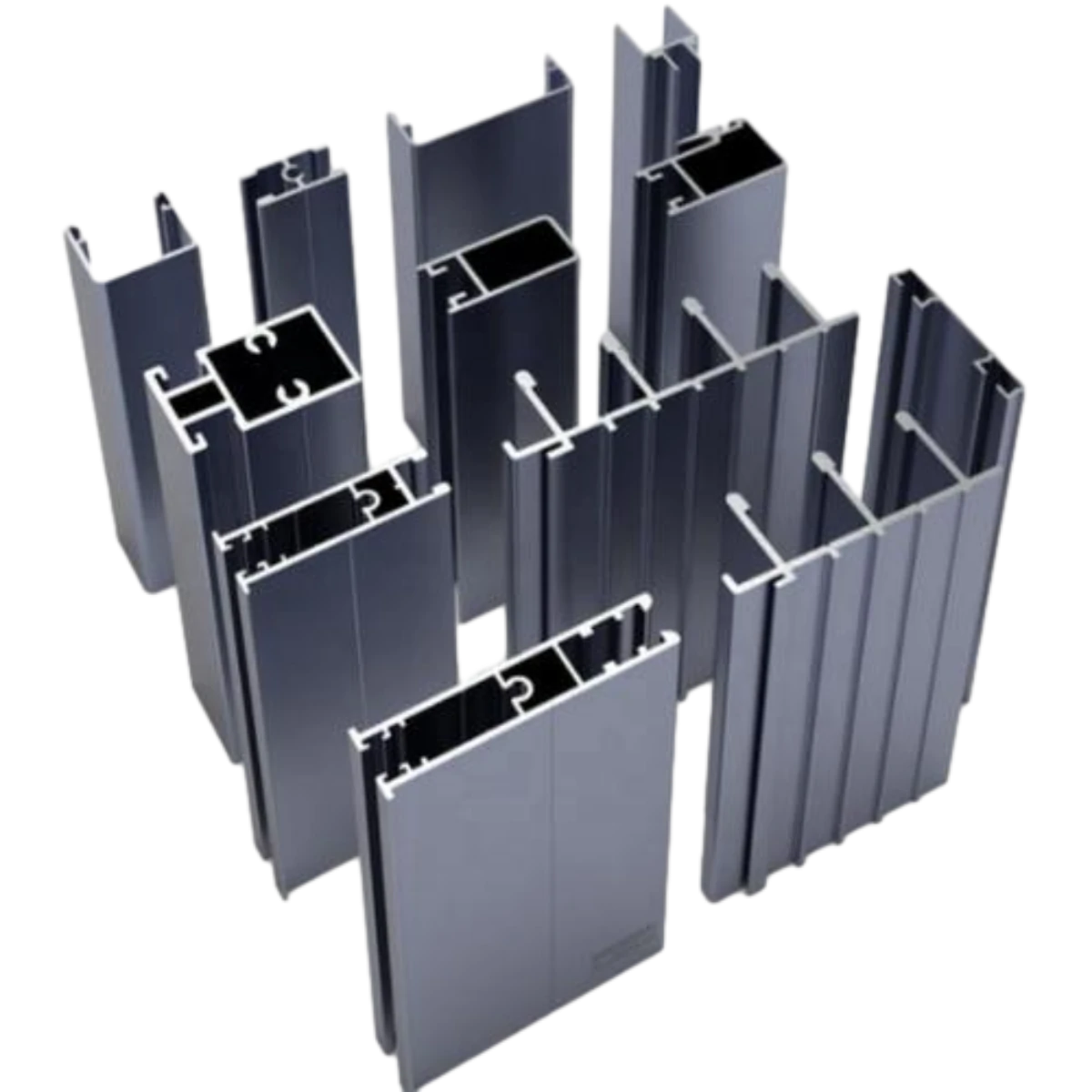

Whether it's a casement, sliding, tilt-turn, or fixed window type, aluminium frames can be tailored to fit different architectural styles, sizes, and shapes Whether it's a casement, sliding, tilt-turn, or fixed window type, aluminium frames can be tailored to fit different architectural styles, sizes, and shapes

Whether it's a casement, sliding, tilt-turn, or fixed window type, aluminium frames can be tailored to fit different architectural styles, sizes, and shapes Whether it's a casement, sliding, tilt-turn, or fixed window type, aluminium frames can be tailored to fit different architectural styles, sizes, and shapes aluminium windows profile. They can also be powder-coated in a wide range of colors and finishes to blend seamlessly with the building's exterior or interior design.

aluminium windows profile. They can also be powder-coated in a wide range of colors and finishes to blend seamlessly with the building's exterior or interior design.3. The color is clean and beautiful: the frame material of the aluminum profile of doors and windows is treated with ammoniated coloring, and has silver-white, bronze, dark red, and other colors, and has a color pattern. The aluminum alloy doors and windows thus have a beautiful appearance, a clean surface, and bright and firm colors, which improve the decorative effect of indoor and outdoor facades. Thermal insulation in aluminum profiles for doors and windows, refractory waterproof corrosion sound insulation, and other properties are wooden windows. Steel windows, with their moderate price, luxurious appearance, diverse styles, good sealing, fire and flame retardant, difficulty in deforming, good strength, easy installation, and exquisite workmanship, are a new generation of door and window materials with broad prospects.

You can easily tune aluminum material to form different preferred shapes. Ideally, the extrusion process allows aluminum for making windows and doors relatively flexible.

Understanding Screen Door Rollers

Standard Packing:

However, plastic taps do have their limitations. They are less durable under extreme pressure or temperatures and may not be suitable for high-performance applications. Users must assess the specific needs of their projects before opting for plastic over metal.

Τάπες Πλαστικές-Μεταλλικές

Aluminum Profiles for Windows and Doors: The Complete FAQs Guide

The benefits of using cast iron for spears lie in its inherent properties. Cast iron, known for its excellent castability, is resilient and suitable for manufacturing sharp, sturdy spearheads that can withstand the rigors of battle. The material's high carbon content contributes to its hardness, allowing for effective penetration without easily blunting. Moreover, the casting process enables the creation of complex shapes that traditional methods cannot replicate, leading to innovative spear designs tailored for specific combat contexts.

cast iron spear

1. Pickets

Powder Coating

Powder coating is a safe, dry finishing process that uses finely ground particles of pigment and resin to create a protective finish. We choose to powder coat our steel frames because it is low in toxicity and has low flammability. The powder coating is then evenly melted and cooled into a thin, durable film. Powder coating can maintain its finish for up to 15-20 years, depending on pre-treatment and the type of powder. Its resistance to weather, corrosion, and chemicals makes powder coating a more durable finish than paint or other liquid coatings.